services list

LASER DIVISION

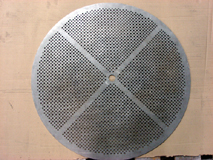

We offer laser cutting as a metal processing solution for a virtually burr-free edge and repetitive consistency each and every time. Additional advantages

We can setup the sheet metal / plate part in-house using our cad programs or work off of our customer supplied cad files. We use a combination of industry standard 2D and 3D software and can import a multitude of file formats.

EQUIPMENT:

3500 watt C02 Laser: Capacity: : 3/4" x 78" x 158" - cut Carbon /Stainless/ Aluminum

BENEFITS:

- Close tolerance (+-.002 Inch)

- No tooling erosion/replacement

- Excellent repeatability

- Clean processing

- Prototype cost reduction

- Decrease secondary finishing

- Material versatility

- Welds with minimal distortion

- Flame/fire polished edge cutting

- Flexibility-fast design achieved with computer controls

- Minimal distortion in heat affected zones

- Non-contact processing eliminates unwanted stress on material